Once We procure rough diamonds from leading mining suppliers, there is assorting department doing this job of rough diamond based on color, clarity, size, cut etc.

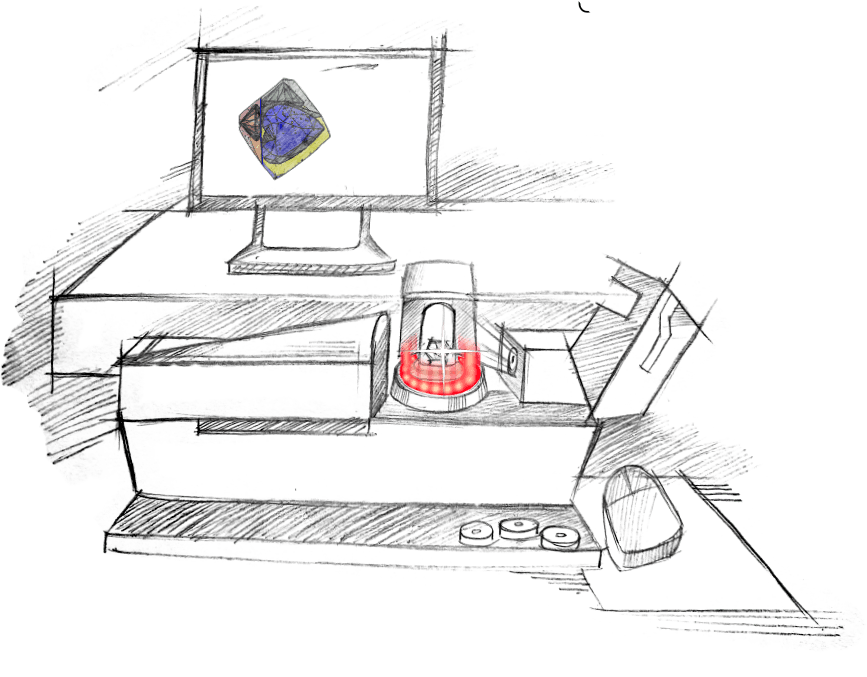

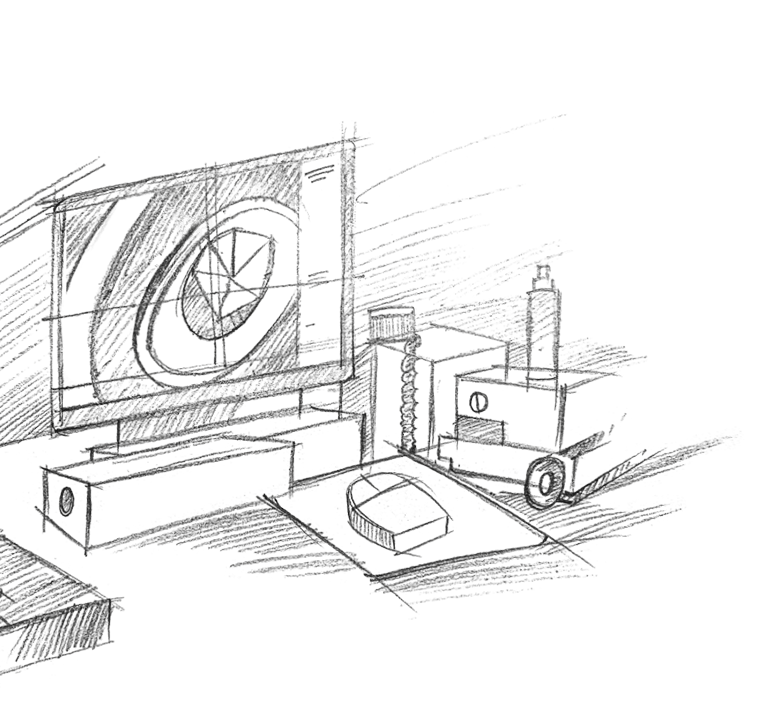

Rough diamond planning is a very important process. Where the department plans the final shape, size, weight and clarity of the diamond. Once, planning by expert staff is done, here they mark the diamond from where the diamond is going to cut.

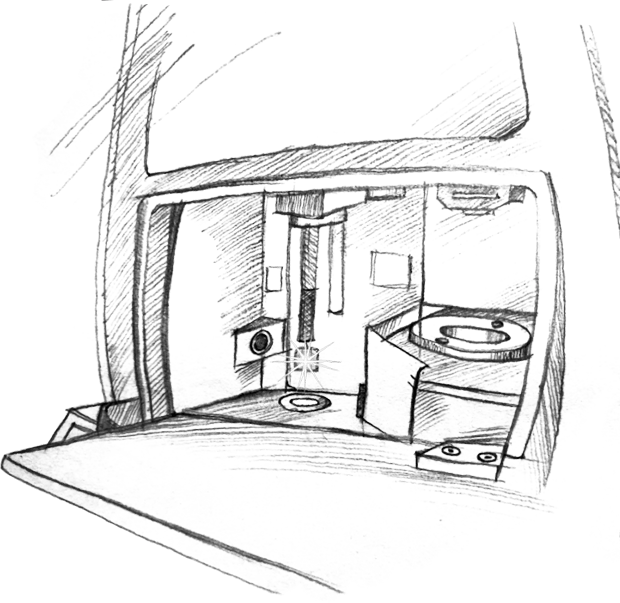

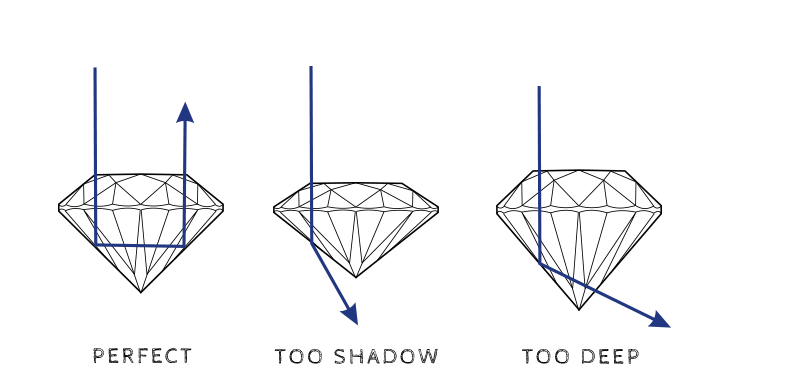

A correct cutting gives the diamond a sharp shine. Even if the diamond's color, size, and weight are correct, it will depreciate without the correct cutting. Cuts Diamond has a procedure that affects its price and appearance. It shines based on the craft with which it is carved. It includes Ideal cut, brilliant cut, step cut, mixed cut, etc.

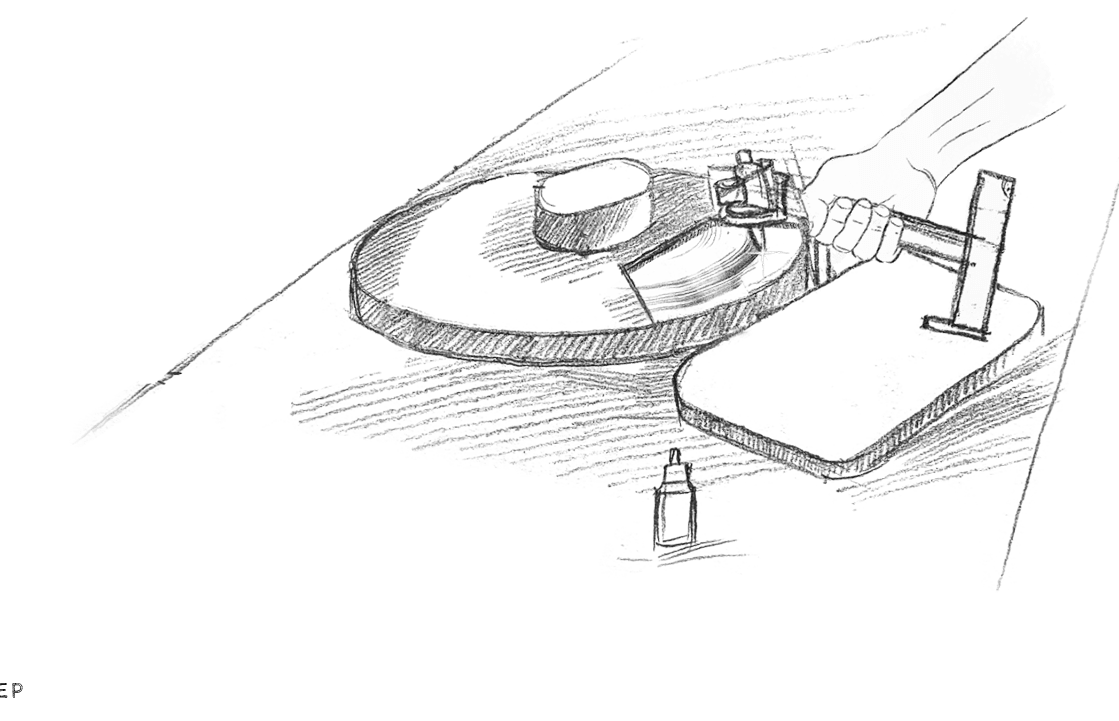

Polishing is the final step in diamond cutting. When the diamond is in rough form, it has to go through polishing, which gives it a beautiful look. It is an art in which concentration and skill are of great importance.

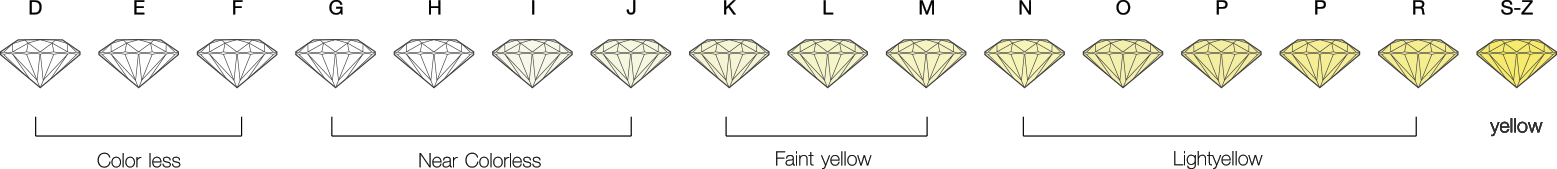

After all kinds of diamond checks, it would be very difficult to tell without an authorized person that this diamond is genuine; for this, the GIA report checks all the reliability, consistency and integrity like color, clarity, cut and carat weight.

Gemological Institute of America. (GIA) is the world’s foremost authority for certification of diamonds, Gemstone and Jewelry. The certificate includes grades for the diamond's carat, cut, color and clarity. The grades are very subjective since an individual looks at each diamond under a loop (10x magnifying glass) and is the opinion of the individual at the lab.